ARES is available in 500 mm and 700 mm deck width versions and undoubtedly stands out as the ideal CMM for workshops.

FEATURES AND BENEFITS

- Ultra-rigid alloy frame to ensure maximum rigidity for scanning applications

- Structure with rapid thermal diffusion for changes in environmental conditions

- FEA-designed bridge girder extrusion, allowing optimal moment of inertia for minimal deflection at high accelerations

- M8 threaded table that fits into the large checkerboard layout.

- Rigid air bearings for high bearing clearance coefficients

- Pneumatic counterbalancing of the Z-axis.

- Free-fluctuation resolution measurement scales of 0.1 micron incorporating dynamic signal processing.

- Fully digital motion control with probe path fusion for optimal performance

- Friction reducers with near-zero hysteresis on all axes

- Passive vibration damping system that isolates external vibrations

- Free access to the measurement area from all sides

- Maximum positioning speed: 517 mm/sec

- Maximum acceleration: 1730 mm/sec2

- Silicon carbide Z-axis column further reinforcing rigidity

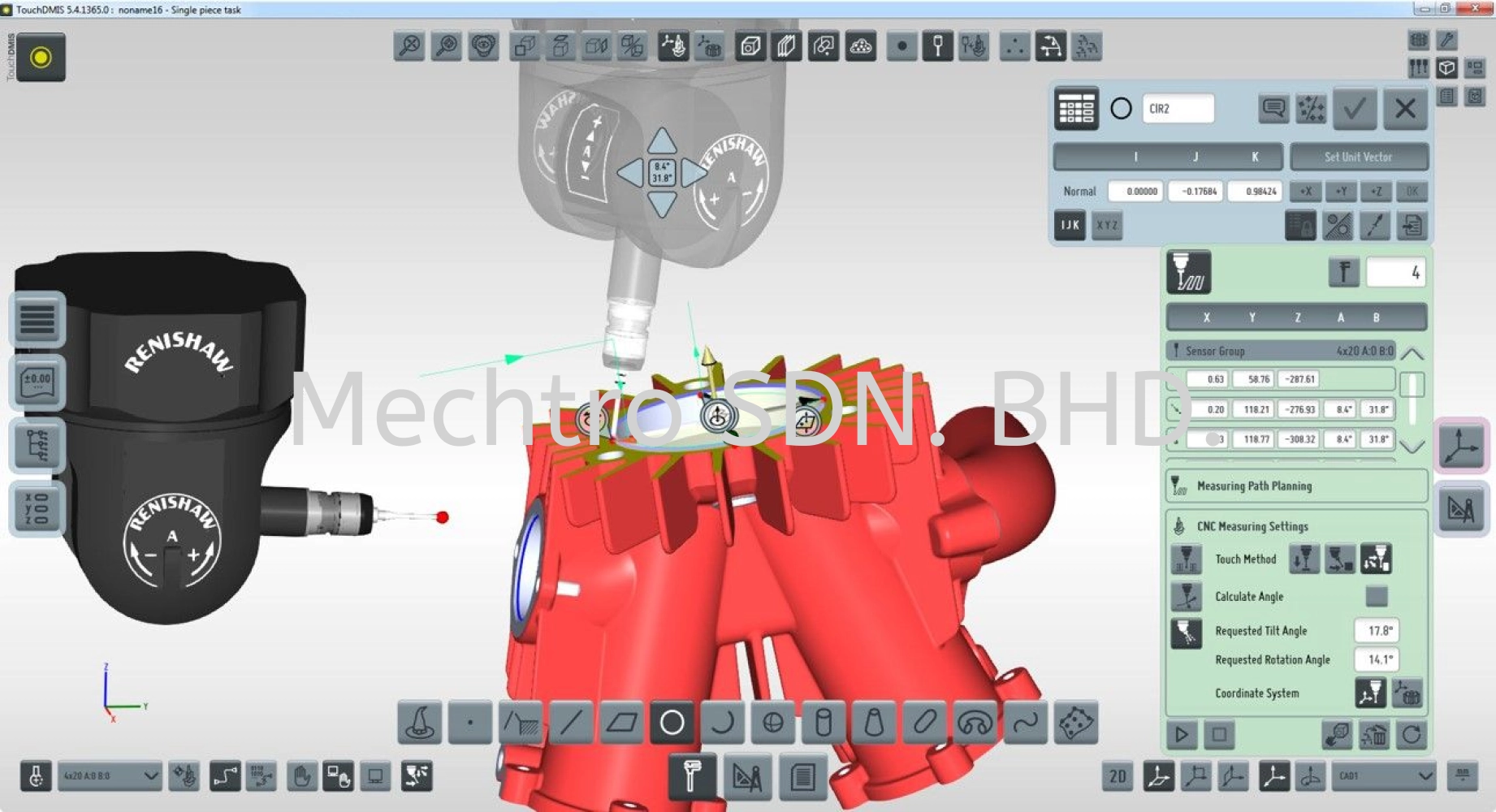

- OptionalRenishaw TONiC resolution measurement scalesof 0.1 micron

- Dynamic wireless temperature compensation system including part temperature sensor.

.png)

.png)

Inquiry - COORD3 ARES NT/NT-L CNC CMM MACHINE